Oct. 10, 2020

During the use and maintenance of Alternator for trucks, the following issues should be paid attention to:

1. The grounding of the battery must be the same as the polarity of the alternator, both of which are negative grounding, otherwise, the battery will be discharged through the silicon rectifier diode of the generator, which will burn the diode.

2. The method of instantaneous grounding (grounding) of the generator output terminal (fire test method) shall not be used to judge whether the generator is generating electricity.

3. When the generator is running at high speed, do not remove the battery and other main electrical equipment to avoid transient over-voltage and damage to the diode, regulator, or other electrical equipment.

4. Check the connection between the generator and the battery frequently to ensure the connection is firm and reliable.

5. Frequently check the tension of the generator belt, and it should meet the factory regulations. If the belt is too loose, it will cause insufficient charging of the battery; if the belt is too tight, it will easily cause damage to the belt and generator bearings.

6. Once the generator is found to be working abnormally, it should be checked in time to find out and eliminate the fault.

7. Maintain the generator regularly. Generally, after the generator has been running for 750 hours or the car has traveled 30,000 kilometers, the brushes, rectifier components, regulators, bearings and other vulnerable components of the generator should be checked and necessary tests.

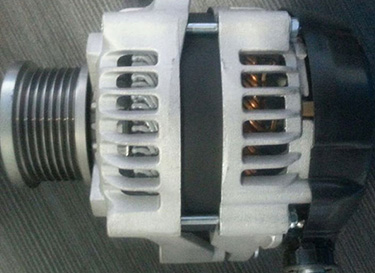

Alternator For Trucks

Testing of generators and charging systems

1. Test of output DC voltage

Start the engine and run it at idle speed. Use a digital multimeter to measure the voltage across the battery.

2. AC component test of output voltage

Use the AC voltage range of the digital multimeter and connect it to the positive and negative ends of the battery to measure the AC voltage output by the generator (the normal value should be ≤0.4V). Specific steps are as follows:

①Start the engine and make it run at 2000rpm;

②Turn on the big headlights and add a certain load to the generator;

③Connect the digital multimeter to the positive and negative ends of the battery and read the AC voltage value. If the voltage is less than or equal to 0.4V, it means that the rectifier of the generator is working normally; if the voltage is greater than 0.5V, it means that the rectifier of the generator is faulty.

Voltage drop test of the charging system

The voltage drop test is mainly used to judge whether the connection between the generator and the battery is good. The specific method is as follows:

①Start the engine and make it run at 2000rpm;

②Turn on the big headlights and add a certain load to the generator;

③Use the DC voltage file of the digital multimeter to measure the voltage drop between the output terminal of the generator and the positive terminal of the battery. The normal voltage value is ≤0.4V. If it exceeds 0.4V, the resistance of the wire connection point is large.

④Use the DC voltage file of the digital multimeter to measure the voltage drop between the generator casing and the negative terminal of the battery and the normal voltage value is ≤0.3V. If it exceeds 0.3V, the wire connection is loose and the resistance of the connection point is large.

Common faults of the charging system

1. Not charging. The possible reasons for not charging are:

① The connecting wire is open, short-circuited, loose connection, etc.

②The generator is damaged. Such as the rotor or stator winding short circuit or open circuit, brush wear, silicon rectifier diode damage, etc.

③The regulator is damaged or the voltage value is too low.

2. Overcharge Overcharge causes the battery life to be shortened, the main reason is that the regulator voltage is too high

3. Insufficient charging. Possible reasons for insufficient charging are:

① The connecting wire has a slight short circuit, loose connection point or poor contact, etc.

②The generator is faulty. Such as short circuit between rotor or stator winding layers, wear of brushes or insufficient spring force, defective silicon rectifier diodes or open circuits of individual diodes, loose belts, etc.

③Improper adjustment of the regulator voltage value (too low).

We are the china Hyundai alternator supplier. If you are interested in our products, please feel free to contact us.

Navigation

Name: Carrie Zhou

Tel: +023-68886580

WeChat: 0086-13650592877

E-mail: carrie@autopartstf-ws.com

Skype: transfortune

WhatsApp: +86 136 5059 2877

Homepage: www.autopartstf-ws.com